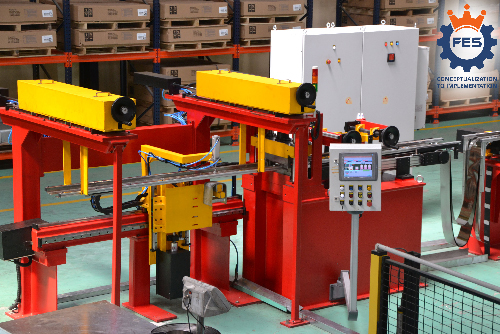

Amorphous Core Cut to Length Lines

The machine is used for making transformer wound core loops of amorphous ribbon. Handling of amorphous thin ribbon in continuous production is tedious. Our state-of-art-technology provides smooth handling and ensured optimum no load losses in the loop. FES machine has a specialty of higher feed accuracies with better staking factor. High speed machine gives an average output of 70-100 MTs per month. (Output calculated based on three shifts, varies with respect to ribbon width and KVA). The machine includes high-speed electronic controllers and all the components are of standard make, thus the reliability is high. The machine has Servo shear along with other three Servo axis which helps in lower maintenance and more user-friendly.